.jpg)

Blogs

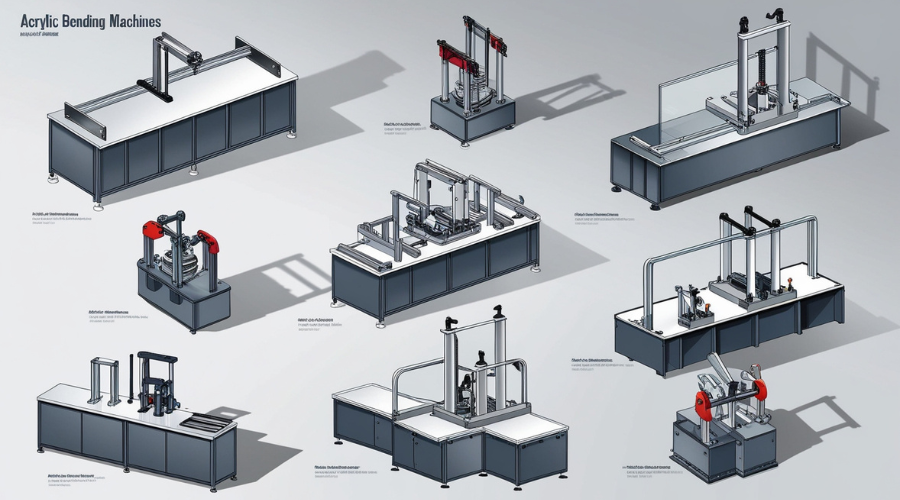

Types of Acrylic Bending Machines

Acrylic is among the most versatile materials. It appears in everyday products such as stores, signs, furniture, and household products. Acrylic maintains its usefulness because it allows processing through various shaping techniques. Manufacturers utilize specific equipment to create diverse acrylic shapes. Specialized tools made for this exact purpose provide the solution.

This blog examines three key acrylic bending machine varieties: oven, vacuum formers, and mechanical benders. It explains machine functionalities, benefits, and drawbacks for specific acrylic materials projects.

Oven Bending Machines

Oven bending is the most popular technique for bending acrylic materials. Heating acrylic creates pliability for bending purposes.

How Oven Benders Work

Imagine an open-top, long, thin oven. Acrylic is heated inside the oven to reach its plastic phase between 290°F and 320°F. At this particular temperature range, acrylic softens to reach pliability.

The process works like this:

- Acrylic sheets need to cover the exposed opening of the oven during this phase.

- Acrylic reaches a soft state when heated for 1 to 3 minutes according to its thickness level.

- The user removes the sheet quickly from the oven before bending it through the use of a template or jig

- The process requires holding the bent acrylic in position while it cools down until the material solidifies

Oven benders are widely popular because they work straightforwardly. They operate with minimal requirements, requiring only heated materials and tools to shape the softened materials.

Advantages of Oven Benders

- Easy to use: Learning the fundamentals of oven bending enables users to perform this technique easily and efficiently.

- Clean bends: The oven-bending process generates exact angles that produce neat material shapes without distortion.

- Less expensive: Strip heaters are among the cheapest oven-bending solutions.

- Versatile: Works with various thicknesses of acrylic

- Line bending: This method creates perfect straight-line bends for constructing boxes, displays, and stands.

Disadvantages of Oven Benders

- Limited to straight bends: The equipment fixes only straight bends, creating no solutions for complex curved or irregular designs.

- Requires practice: Acquiring professional heating timing skills demands minimal practice with oven benders.

- Risk of bubbles: Acrylic exposed to excessive heat develops bubbles while it turns white.

- Manual operation: The bending process happens manually, introducing potential human mistakes during operation.

Vacuum Forming Machines

When creating complicated shapes with curved outlines, vacuum forming machines represent the best solution.

How Vacuum Formers Work

The vacuum forming procedure works through the creation of plastic object molds. Here's how it works:

- Acrylic sheets are clamped inside frames that hold them above buck molds.

- The material reaches pliability when it reaches an optimal heating temperature.

- The heated flexible material is dropped onto the mold surface.

- The vacuum creates full pressure between the sheet and mold, making the acrylic adopt the exact mold shape.

- After the cooling process, the acrylic product can be obtained from the manufacturing stage.

Vacuum formation creates complex forms that standard bending techniques cannot produce. This is why you can see the distinction between making creases in paper and applying balloon stretch around something.

Advantages of Vacuum Formers

- Complex shapes: Vacuum Forming enables users to make detailed, complex-shaped items from one piece of acrylic.

- Consistent results: The device generates matching duplicates after setting up its operation correctly.

- Complete reproduction: Vacuum Formers successfully reproduce precise details of the mold with their advanced features.

- Efficient for production: This machine provides excellent efficiency for creating many identical items simultaneously.

- Variety of thicknesses: Works with thin to medium thickness materials

Disadvantages of Vacuum Formers

- More expensive: Requires more equipment than simple oven benders

- Requires molds: Any application requires mold development for individual designs.

- Material thinning: Acrylic becomes thinner because it is stretched across the mold surface.

- Size limitations: Your vacuum forming bed determines the maximum dimensions you can work with.

- Learning curve: Users need more technical ability to operate vacuum formers than other bending approaches.

Mechanical Bending Machines

Mechanical bending machines use force to replace heat during the acrylic bending process.

How Mechanical Benders Work

The bending process with mechanical benders happens on cold acrylic through pressure application instead of heating. The available bending machines include various designs, with the press brake, CNC, and manual brake benders being the most popular options.

- Press brakes: Press brakes represent large machines that employ a die and a punch tool for material bending.

- CNC benders: The CNC bender operates under computer control to produce exact and repeated angular shapes.

- Manual brake benders: Manual brake benders represent basic versions that carry out bending operations through leverage mechanics.

The process typically involves:

- The acrylic sheet must be positioned precisely in its place within the machine.

- A proper bending pressure is applied through the bending element. The machine equipment applies force, which induces acrylic material bending at specified angles.

- This process finishes immediately because it requires no waiting time for cooling.

Advantages of Mechanical Benders

- Speed: The bending process requires no heat or cooling phases.

- Precision: The machine enables users to generate precise bending angles.

- Consistency: Produces identical results every time

- No material discoloration: Acrylic remains free from discoloration because heat is not a factor that causes color changes or bubbling effects.

- Automation potential: Some mechanical benders allow automatic operation through programmed sequences.

Disadvantages of Mechanical Benders

- Limited materials: Works best with thinner acrylic sheets

- Risk of cracking: The Main safety hazard occurs when heat is absent because this leads to potential fractures.

- Limited to simple bends: Complex acrylic shapes cannot be bent using standard mechanical bending techniques

- Higher cost: Using professional mechanical benders will increase your costs.

Final Thoughts

The process of bending acrylic plays a critical role in creating contemporary products. The bending method determines the production quality and efficiency of any sign, display box, or car part creation project. Each technique, oven bending, vacuum forming, and mechanical bending, maintains distinct positions within production settings.

Understanding machine strengths and weaknesses optimizes time, finances, and material use. Beginners and small businesses succeed with oven or mechanical bending. Large-scale production requires vacuum forming technology.