Weifang Aokai CNC Equipment Co., Ltd.

We are professional manufacture of advertising machines, such as letter bending machine, laser welding machine, UV curing machine, fiber laser cutting machine, cnc router, laser marking machine, 3D printer etc .

View Details

Weifang Aokai CNC Equipment Co., Ltd.

We are professional manufacture of advertising machines, such as letter bending machine, laser welding machine, UV curing machine, fiber laser cutting machine, cnc router, laser marking machine, 3D printer etc .

View Details

Weifang Aokai CNC Equipment Co., Ltd.

We are professional manufacture of advertising machines, such as letter bending machine, laser welding machine, UV curing machine, fiber laser cutting machine, cnc router, laser marking machine, 3D printer etc .

View Details

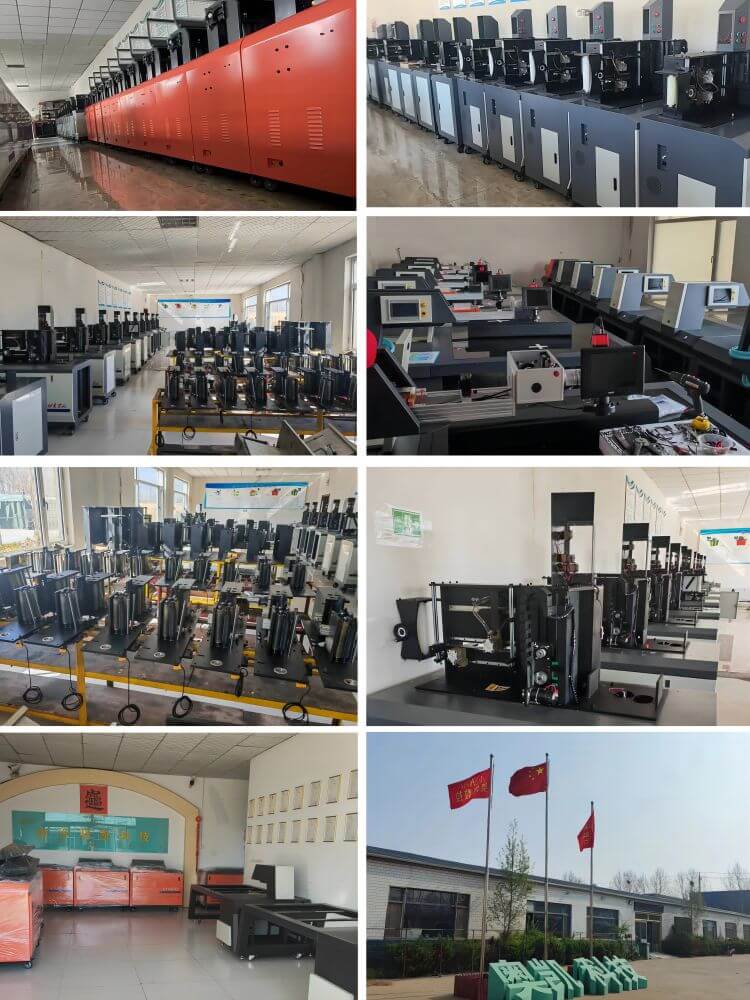

About Us

Weifang Aokai CNC Equipment Co., Ltd.

We are professional manufacture of advertising machines, such as letter bending machine, laser welding machine, UV curing machine, fiber laser cutting machine, cnc router, laser marking machine, 3D printer etc .

We have high professional technology team with 15 years experience.

We have export machines to more than 20 countries.

We are still looking for good resealers all over the world.

Waiting for your coming.

Services

High Quality Production

With state of art production facility, we take pride in providing the quality of the highest standard guaranteed.

Lead Time Assurance

Our efficient production facility, ensures timely lead time for all the incoming orders.

Reliable Service

Excellent customer services is our main scope. We take special care of the customer experience.

Low Cost

With state of art production facility, we take pride in providing the quality of the highest standard guaranteed.

Products

Our Gallery

Categories

Our Blogs

Types Of UV Curing Machine and Their Maintenance

Curing with UV light is very similar to baking a cake. As long as the temperature of the oven is correct and the batter stays in it long enough while being "cooked," a good quality cake will be produced. When curing with UV materials, if the materials receive the correct wavelength of light intensity for the specified amount of time, a proper cure will occur, regardless of whether the light is generated from an arc lamp, a microwave unit, or any UV LED. The properties of the light are what matter in the cure process of a UV ink, coating, and adhesive. Choosing the right UV light source to install is like selecting the right oven for your kitchen. While some ovens may produce the same result, the ultimate choice will depend on other factors such as costs, size, features, quality or reliability. We know that buying equipment is a big decision and that is why in this blog we will ease the decision-making process for you by clarifying the differences between various UV curing machines and what to consider before making the big purchase decision. Comparison of Different Types of UV Curing Machines Type of Machine Key Features Best Fit Applications Buyer Advantage Conveyor UV Curing Continuous belt system, uniform curing, supports high-volume production Packaging, automotive components, electronics assembly Maximizes throughput and minimizes bottlenecks Spot UV Curing Pinpoint precision, localized curing, compact systems Electronics assembly, medical devices, adhesives for small joints Ensures accuracy where detail is critical Flood UV Curing Coverage area is great and light exposure is uniform. Coatings, displays, panels, protective layers Guarantees even curing across large surfaces Handheld UV Curing Portable and flexible and the small size is easy to maneuver. Repairs, custom projects, small-scale production Adds mobility and adaptability to workflows LED UV Curing Energy-efficient with a long operational life. Delivers immediate start, and custom wavelength regulation. Printing, adhesives, coatings, sustainable manufacturing environments Reduces energy costs, lowers maintenance, eco-friendly Tunnel UV Curing Enclosed curing environment, and perfect fit for larger or complex products Wood finishing, automotive parts, large-format printing Delivers consistent curing for bulky or high-value items What to Look Before Buying UV Curing Machine Maintenance Ease When examining a new UV light source, consider how simple it will be to repair and maintain for peak performance. What is the method to clean a soiled reflector? How fast can you change the bulb? What is the price of spare parts? These are vital considerations that matter a lot in the long run. Certain arc lamps offer rapid-change features, featuring lamp modules that can be swapped out swiftly and effortlessly like a toner cartridge, whereas alternative designs necessitate almost taking apart the system for a standard procedure. For LED sources, you should assess if the LED array can be serviced in the field, or if the whole unit needs replacing in case of an issue. Certain LED designs include plug-in modules to ease on-site maintenance. Overall, uncomplicated wiring with minimal connectors and the least number of moving components simplifies maintenance. Certain UV systems enable easy adjustments to power output levels, offer insights into the state of the power supply or cooling system, and deliver diagnostic details in case of issues. Certain LED systems protect the array by tracking vital factors of the systems, including cooling temperature and coolant flow rate. More advanced LED control systems offer “addressability” that allows you to selectively activate or deactivate different sections of the array to fit various sized components. When evaluating a light source, you should think about how it will fit into your curing line or equipment and if it possesses the necessary interface features Evaluate the Energy Efficiency What makes UV light curing systems better than traditional curing counterparts is their enhanced energy efficiency and reduced environmental impact when compared to conventional curing methods. When selecting a system, your emphasis should be on reducing your operational expenses so choose a model that has reduce energy consumption and does not cause unnecessary waste. , thereby lowering operating costs and promoting sustainability. Consider Your Budget When obtaining a UV light curing system, consider not only the initial purchase price but also the overall cost of ownership. This includes aspects such as upkeep, energy consumption, and replacement components. A system that comes with a greater initial investment may offer greater long-term value if it requires less maintenance and consumes less energy. Technical Support All suppliers guarantee excellent service and assistance. How can you make sure that you choose someone who assists you when facing an issue or requires technical support? Certain behaviors you can notice prior to purchasing serve as reliable signs of what to anticipate later. Ensure that your product is backed by comprehensive operating manuals and technical documentation. The vendor’s site may also include technical documentation such as manuals, downloads, and useful videos. Vendors that have their own repair facilities and service staff are a positive indication. In the development phase, suppliers ready to offer testing equipment and on-site assistance to guarantee a solid process might also be more inclined to provide increased support in the long term. Conclusion It’s easy to think that UV curing equipment serves the same function. The question is, are you willing to take the risk of acquiring the wrong UV curing equipment to potentially slow your operation down, waste energy, or even compromise quality? The scale of production, level of accuracy needed, and type of materials that need curing will determine which machine will be right for your operation. For example, be prepared for mass production. Conveyor or tunnel systems will probably be the most effective. If your work requires incredible accuracy, use spot curing systems. If you need something portable, handheld tools will give you maximum mobility. As for operating costs, LED systems are something to consider for better ROI over the life of the equipment.

Laser Welding 101: A Beginner's Guide to the Technology

Many people wonder how car parts and medical devices get their precise connections and discover that laser welding is a crucial technology. Laser welding is a thoroughly developed industrial process that operates in numerous modern production sectors. What Exactly is Laser Welding? A laser beam creates the basis for welding two materials together. A laser generates a heat concentration that vaporizes material around the joint area as the welded pieces combine during cooling. A laser is a highly accurate and powerful light tool that melts plastic and metal materials at their designated spot. The process delivers quick results with high accuracy and maintains a clean operation. How Laser Welding Works? The procedure of laser welding functions by applying a rugged laser beam toward the location where two parts need to connect. A computer system enables precise control of this beam, ensuring excellent operations accuracy. The typical procedures operate as follows: The two welding components remain near each other. The laser beam generates powerful heat when focusing on the seam area. The materials experience melting during the moment of contact. When the laser beam shifts or stops emitting heat, the melted section returns to solid form while cooling down. The two parts have become one unified structure through the procedure. Different Types of Laser Welding Among various laser welding types, the primary ones used are: Conduction welding: Laser welding through conduction involves heating only the outer layer of metal materials. The heating process of a stove pan spreads its heat evenly throughout the metal material. The welding process produces neat and smooth results for thin materials. Keyhole welding: During keyhole welding operations, the laser power is high enough to generate a hole through the metal. The hot metal vapor enters through the "keyhole" opening, enabling the laser beam to penetrate deeper into the material. The laser path triggers molten metal to follow behind until it solidifies. The welding process provides excellent outcomes on thicker materials and generates extremely robust welds. Laser Welding Benefits Laser welding has several benefits which give it an edge over traditional welding: 1. High Precision Laser welding works exceptionally well to join delicate or miniature components. A laser beam delivers precise heat to narrow spots, leaving the adjacent material unharmed. 2. Fast Process Laser welding is quick. The process completes material fusion at a faster rate than standard welding techniques, which enhances production speed. 3. Clean Welds Laser welding produces minimal smoke and spatter, thus resulting in easy cleanup and better final appearance. 4. Less Heat Damage The laser produces a narrow beam that prevents heat from affecting extensive areas. Nearby components stay protected from damage because of this method. 5. Automated Friendly Laser welding operates smoothly with robotic systems and machine-based automation. Manufacturers who need repetitive welding operations benefit substantially from this method. Common Applications of Laser Welding Laser welding operates beyond high-tech laboratories because multiple industries with unexpected applications utilize this technology. Car manufacturing: Laser welding techniques make the sophisticated shapes of automobile bodies possible. Many are laser welded. Laser welding is popular with automakers because it is strong, accurate, and machine-operated. Medical devices: The welding of medical devices requires perfect connections without contamination affecting surgical tools or pacemakers. The welds produced by laser technology work exceptionally well with delicate materials. Jewelry making: Laser welding serves jewelry making by repairing and connecting delicate jewelry components that traditional welding heat would damage. Electronics: Your mobile phone and computer contain electronic components combined with laser welding techniques. Laser welding is the sole choice for joining small parts that measure below the size of a grain of rice. Aerospace: Laser welding technology makes it possible to join airplane parts in a way that is both strong and safe for people. Challenges of Laser Welding Laser welding faces challenges similar to other technologies, which makes it unsuitable for all applications: Purchasing and keeping laser welding machines requires significant financial investment. The cost of acquiring a quality laser welding system ranges from tens to hundreds of thousands. Safety Needs Demand attention due to laser power capabilities that melt metals, which makes them Dangerous to People. The execution of special safety measures and training constitutes an essential requirement. The laser welding process excels with various metal types but encounters difficulties working with copper because the laser beam reflects from shiny surfaces instead of getting absorbed. Proficient technical expertise is required to establish an excellent laser weld because it demands an understanding of materials and laser equipment. Welding requires more than basic knowledge of holding a welding torch to begin. The Future of Laser Welding Laser welding technology keeps improving. New developments include: Fiber Lasers: Fiber Lasers establish themselves as more efficient and reliable laser types, which reduces barriers to technological accessibility. Hybrid Systems: Modern welding operations integrate laser technology with conventional systems to leverage their advantages. More innovative Controls: Advanced sensors and algorithms automatically change laser power and speed to provide the best results, allowing real-time weld monitoring. Final Words Laser welding operates by applying intense light beams to create metal welds despite their initial complex appearance. This technology has become highly sought after in various industries because of its precise nature, strong performance, and clean joining capabilities. Knowledge about laser welding technology enables potential users to discover its potential for creating strong, precise metal joints in their projects. Due to decreasing costs and improved equipment usability, laser welding technology will expand into additional uses. FAQs 1. What is laser welding, and how does it work? Laser welding is a precise and high-speed welding process that uses a focused laser beam to melt and join materials, usually metals. The intense heat from the laser creates a small, deep weld pool, allowing for strong and clean joints with minimal distortion. 2. What materials can be welded using laser welding? Laser welding is well-suited for a variety of metals, including stainless steel, carbon steel, aluminum, titanium, and even dissimilar metal combinations. It’s commonly used in industries like automotive, aerospace, medical devices, and electronics. 3. What are the advantages of laser welding over traditional welding methods? Laser welding offers several benefits: High precision and control Minimal heat-affected zone Faster processing speeds Cleaner and stronger welds Less post-processing or cleanup required 4. Is laser welding suitable for beginners or DIY projects? While laser welding is highly efficient, it requires specialized equipment and safety precautions. It’s not typically recommended for beginners or casual DIY enthusiasts unless they’ve received proper training and have access to the right tools. 5. What safety precautions should be taken when laser welding? Laser welding can be hazardous without proper protection. Operators should use appropriate eye protection, wear protective clothing, and ensure the workspace is equipped with laser safety barriers and ventilation systems to avoid exposure to laser radiation and fumes.

Understanding CNC Routers: A Beginner's Guide

People who listen to others talk about CNC routers often get confused about what they are. A simple understanding of CNC routers shows they have developed into intriguing devices. This blog explains CNC routers, including their functionality and applications, and details their widespread adoption across industries and individual usages. We will simplify the explanation of CNC routers and how they work to help beginners understand them. What Is a CNC Router? A CNC router is a brilliant machine designed for cutting operations. It operates under Computer Numerical Control since a computer system manages the machine's movement patterns and cutting capabilities. With the help of software instructions, this gadget operates like an automated carpenter. A CNC router uses bits to cut various materials, including soft metals, plastic, and wood. This intelligent machine shapes materials through cutting movements akin to pencil drawings. How Does a CNC Router Function? The process consists of three easy stages. • Design: In the first step, you design your project using CAD software on a computer system, which stands for Computer-Aided Design. You develop an electronic design representation that functions as a digital blueprint. • Convert: After creating the design, you must transform it into a set of programming instructions, which the CNC router understands as G-code. The machine receives instructions that indicate its location points and cutting timing. • Setup: You set up the CNC router process by placing your material onto the table and securing it for static operation during the cutting phase. • Run: After receiving your instructions, the CNC router moves its cutting tool according to your design. • Finish: You will find your completed workpiece when the machine completes its operation. Parts of a CNC Router A CNC router contains multiple essential elements that include: • Frame: The machine body functions as its primary structural component, maintaining all components properly. Its structural integrity must be high to avoid machine vibrations when performing cuts. • Bed: The flat surface, known as the bed, receives the material placed on it. The material stays secure on the bed because it contains clamps or vacuum systems for holding purposes. • Spindle: The spindle unit maintains and rotates the operational cutting device like a mighty drill. • Motors: These move the spindle around in different directions. Most CNC routers move in three directions: left-right motion (X-axis), front-back movement (Y-axis), and vertical movement (Z-axis). • Controller: The machine's central processing unit interprets computer commands to direct motor operations. Types of CNC Routers Different CNC router models exist in numerous dimensions: • Hobby/Desktop CNC Routers: Hobby/Desktop CNC Routers are minor machine versions that operate from desktop surfaces. Their compact design suits novice users who create small wooden products such as signs, decorative pieces, and models. Small projects involving softer materials cost less, but the machines cannot handle large or dense cutting operations. • Mid-size CNC routers: Mid-size CNC routers provide large-scale capabilities with high power and serve businesses that operate at a small scale or are intense hobbyists. The machines operate on bigger tasks while handling dense materials. • Industrial CNC Routers: Industrial CNC Routers are large, heavy-duty equipment in industrial workplaces and big workshop environments. These machines operate endlessly yet require extensive funding and production facilities. Benefits of CNC routers You can make almost anything with a CNC router, but here are some common ones: • Toys and game pieces • Parts for larger projects • Custom decorations • Signs and lettering • Furniture parts • Cabinet doors • Guitar bodies • 3D carvings and artwork • Custom plaques Materials Selection The CNC router technology accepts numerous material types for processing. Your learning experience will clarify each material's required cutting speeds and tool types. • Wood: The CNC router operates on wood varieties from plywood to MDF alongside hardwoods and softwoods. • Plastics: Other types of plastics include acrylic, PVC, and HDPE. • Soft metals: The machine needs high power for aluminum, brass, and copper; steel and iron are off-limits. • Foam: Foam becomes appropriate for signboards, decorative props, and packaging applications. • Composites: Materials like carbon fiber or fiberglass. Getting Started with CNC Routing The process to start CNC routing consists of several steps. 1. Learn the Software Learning CAD software must be your first step before operating any machine. Free options include: • Fusion 360 (free for hobbyists) • FreeCAD • SketchUp Free You will need CAM software (Computer-Aided Manufacturing) to convert your designs into machine instructions. The majority of CAD software applications include integrated CAM functionality. 2. Choose Your First Machine For beginners, consider: • A desktop CNC router kit • A used entry-level machine • Joining a local maker space will provide access to their CNC router equipment Purchasing your initial machine should not be an impulse purchase of the cheapest option available. 3. Start with Simple Projects The learning process should start with basic flat designs preceding attempts at advanced 3D carvings. Good starter projects include: • Simple signs • Coasters • Basic brackets or joins • Nameplates • Simple decorative items 4. Safety First Safety is still paramount during CNC router operations, even if the machines offer better surroundings than usual workshop equipment but still call for correct safety procedures. • Always wear safety glasses. • Wear protective ear devices because CNC routers generate substantial noise levels. • You should tie your long hair back while avoiding loose-fitting clothing. • Avoid reaching into the machine when it operates. • Dust collection systems should be used whenever possible because cutting operations generate excessive dust. Standard Terms You Will Hear The following terms will likely create confusion for beginners who learn about CNC routers: • Bit: The spinning tool called Bit functions as the material removal component. • Feeds and Speeds: The machine operates at a specified feed rate speed while the cutting tool rotates at a particular speed due to feeds and speeds. • Toolpath: Your cutting tool will trace a specific path known as a toolpath. • Pockets: Pockets represent the operational areas that do not penetrate material fully. • Profile Cuts: The material receives complete cuts from Profile Cuts. • Tabs: You need tabs that function as small, unmodified sections that maintain your workpiece position during cutting. • Depth Per Pass: A cutting operation should only reach this specified depth before the tool makes another cycle. • Stepover: When removing material from an area, the bit overlaps with past cuts, an amount referred to as stepover. Common Mistakes to Avoid The beginning stage of learning involves making errors by everyone. Here are some common ones: • Rushing during cutting operations leads to broken bits and rough surface quality. • Multiple shallow cuts are more effective than performing one deep slice. • The improper fixation of material will cause your project to fail because the material shifts during cutting. • Selecting inappropriate bits for different materials and different cuts is a mistake. • The diameter of your bit creates a circular radius because the bit has thickness when you cut inside corners. • The dust produced during CNC routing requires sufficient dust management planning. Tips for Success • Online tutorials provide numerous free educational videos about CNC techniques. • Many helpful CNC enthusiasts exist in both forums and Facebook groups online. • Write down successful and unsuccessful techniques in a project notebook for future reference. • Use inexpensive wood as your first material when learning CNC operations. • Follow the manual instructions to maintain your machine by cleaning it and applying lubrication. • Learning CNC routing requires patience since practice makes it easier to master. Is CNC Routing Right for You? The CNC routing system suits your needs if you meet these three criteria. • Your interests include computer work as well as physical craftsmanship skills • You prefer manufacturing things that need accuracy and repetition in their outcomes. • You possess sufficient area for the equipment and dust collection systems. • You have both the ability to wait patiently and you enjoy learning new abilities. It might not be ideal if: • Do you prefer purely hand-crafted work • You're looking for instant results • You have minimal space • You're uncomfortable with computer design Final Thoughts The CNC routing system enables technical makers to create practically any shape. The initial difficulty of learning brings rewarding outcomes for CNC users. Your CNC router will generate precise and sophisticated items that cannot be duplicated manually. All experienced CNC operators learned their skills from the beginner stages. The foundation of learning CNC starts with a dedication to gradual progression and embracing every mistake because this method helps us understand new things. After gaining enough experience, you will begin designing and creating exceptional projects using your CNC router.

Top Advertising Machine Supplier for Signage Parts Production – Aokai CNC Equipment

Looking for reliable and efficient machines to streamline your signage production process? Weifang Aokai CNC Equipment Co., Ltd. is your go-to advertising machine supplier, offering a wide range of CNC machines specially designed for manufacturing signage components with precision and speed. Whether you're cutting, bending, welding, or UV curing, our advanced machines are built to enhance productivity and elevate your business's output.

Vast Collection of Machines for Different Production Types

Businesses that manufacture signage and similar outdoor advertisement products need us. We are an advertising machine supplier with CNC machines for different functions. Each machine has a unique function that helps to achieve a higher output level. We offer these CNC machines for different operations because we have a wide connection.

· Marking

· Routing

· Welding

· UV curing

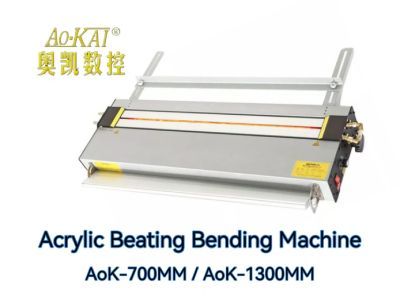

· Bending

All these machines have CNC systems to speed up the process. Then, you will get speedy and precise outcomes together. We work on their accuracy level for better customer satisfaction.

Best Solutions for Outdoor Advertisement Businesses

Outdoor advertisement needs frames and boards with large and small letters. We have machines that can meet your demands. Weifang Aokai CNC Equipment supplies machines that perform different functions based on your selected type. Our objective is to provide you with the finest machines for each application. Our machine can do much if you want to cut, weld, bend, or UV cure. Businesses can get lots of advantages once they start using our machines. They will meet the objectives of advertisement boards and signages.

We Have Prices That Suit Your Budget

Find these economic prices from Weifang Aokai CNC Equipment. Our machines for advertisement boards and signage are affordable. Small businesses can afford them, and large companies can purchase multiple units. We make it easy for everyone in the advertisement products industry.

Our Supply Will Reach Global Destinations

Our supply is available internationally, which shows our strength in worldwide competition. Contact us for details and a quotation to learn more about international supply.

All Machines are Easy to Operate and Maintain

Weifang Aokai CNC Equipment manufactures machines for easy operation. Users can operate them through their simple CNC system, which makes our machines manageable at different industry levels. Small, medium, and large businesses can use them to produce signage and advertisement boards. Their parts replacement process is also easy to handle. Overall, maintenance is simple for users. Our customers can contact us for any support they want.